FLEX P台式粒子成像系统,ZebraSCI Flex P无损颗粒检测系统详细介绍:

FLEX P台式粒子成像系统,ZebraSCI Flex P无损颗粒检测系统是由美国ZebraSCI研究开发并生产的。

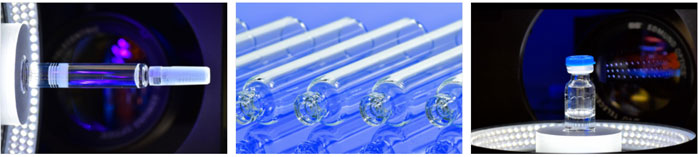

经过验证的Flex P可无损地解决容器中的颗粒数量和尺寸分布。该系统对计数和跟踪溶液中的亚可见和可见粒子很敏感。跟踪算法很重要,因此该机器减少了重复计数,并且可以对溶液中的颗粒进行表征,而其他视觉系统却被容器上的颗粒和表面缺陷所迷惑。跟踪算法也很重要,因此气泡不会被视为颗粒。Flex P系统旨在适应各种常见的主容器尺寸而无需更换零件。Flex P系统核心的光学和自动化与我们的高速卫星系统相同,但设计紧凑且非常适合实验室环境。

FLEX P台式粒子成像系统,ZebraSCI Flex P无损颗粒检测系统规格:

110-240VAC,单相,50 / 60Hz

额定功率:400W(最大)

配方开发

机器尺寸:60cm X 30cm X 53cm

气压:90 psi

符合CE要求

FLEX P台式粒子成像系统,ZebraSCI Flex P无损颗粒检测系统应用与优点:

在存在各种药物产品的情况下观察并计数可见/可见的颗粒

表征溶液中的分布/数量颗粒

配方开发

稳定性研究

集装箱资质

ZebraSCI Flex P– non-destructive particle inspection systems

The Flex P is validated to resolve quantity of particles and distribution of sizes non-destructively in containers. This system is sensitive to count and track sub-visible and visible particles in solution. The tracking algorithms are important so that the machine has reduced double counting as well as particle in solution can be characterized where other vision systems are fooled by particle and surface defects on the container. Also tracking algorithms are important so that air bubbles are not considered particles. The Flex P system is designed to accommodate a range of common primary container sizes without changing parts. The optics and automation at the heart of the Flex P system are the same as our higher speed satellite system, but are designed to be compact and well suited for lab environments.

ZebraSCI Flex P SPECIFICATIONS:

110-240VAC, Single Phase, 50/60Hz

Power Rating: 400W (maximum)

Formulation Development

Machine Dimensions: 60cm X 30cm X 53cm

Pneumatic Pressure: 90 psi

Meets CE requirements

ZebraSCI Flex P APPLICATIONS & BENEFITS:

Observe and count subvisble/visible particles in the presence of various drug product

Characterize the distribution/quantity particles in solution

Formulation Development

Stability Studies

Container qualification

SAG: FLEX P,FLEX P粒子成像系统,FLEX P台式粒子成像系统,ZebraSCI Flex P,ZebraSCI无损颗粒检测系统,ZebraSCI Flex P成像系统